The lotus leaf’s remarkable ability to repel water has inspired a revolutionary approach to surface engineering, transforming how we design materials that interact with liquids.

🌿 The Natural Marvel: Understanding the Lotus Effect

Nature has perfected the art of water repellency over millions of years, and few examples are more striking than the sacred lotus flower. Despite growing in muddy ponds, the lotus leaf remains pristine and clean, with water droplets rolling off its surface like mercury on glass. This phenomenon, scientifically termed the “lotus effect,” represents one of nature’s most elegant solutions to staying clean in a dirty environment.

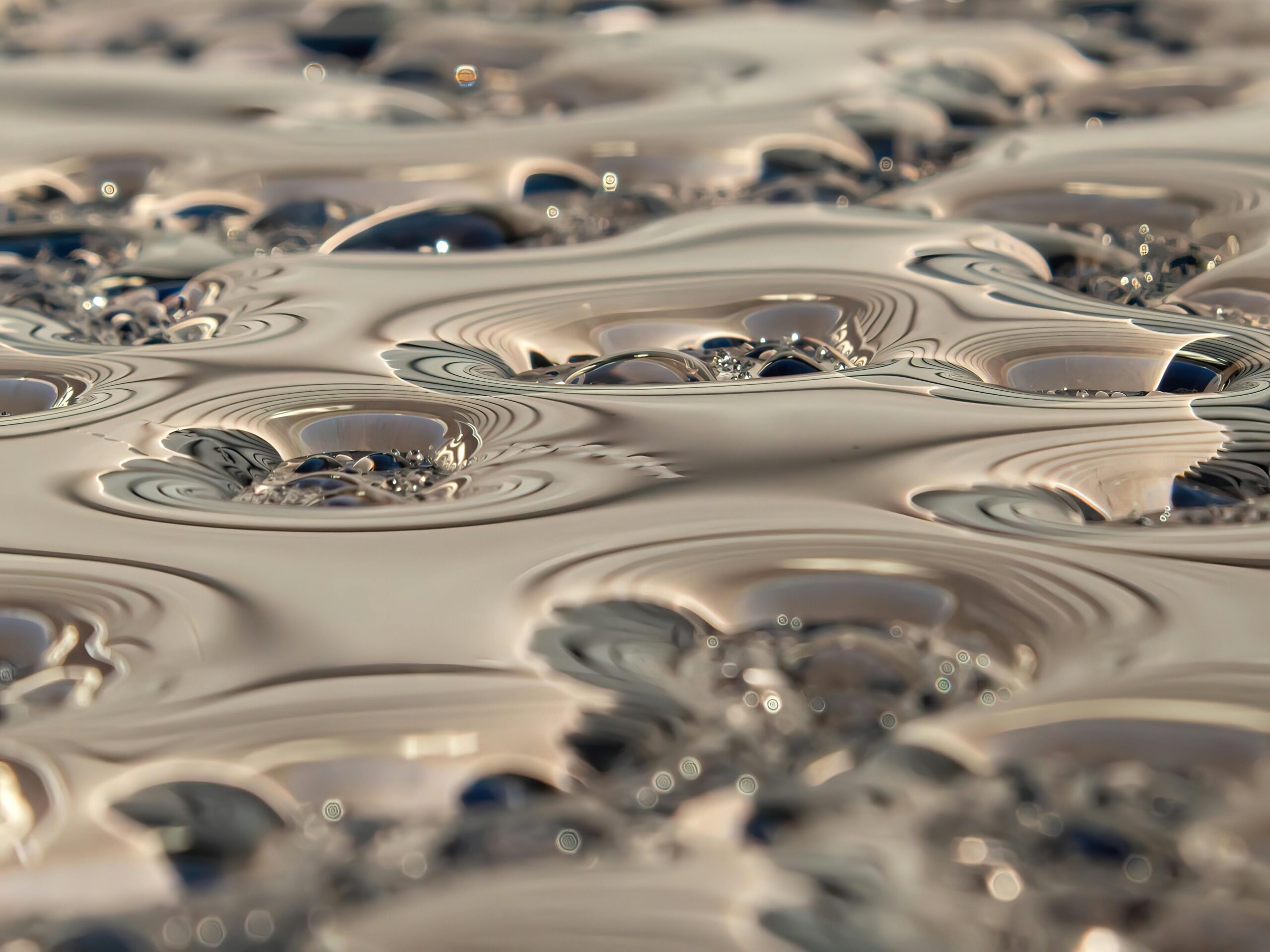

The secret lies not in any chemical coating, but in the microscopic architecture of the leaf’s surface. When examined under powerful microscopes, the lotus leaf reveals a complex landscape of tiny bumps and waxy crystals that create a dual-scale roughness. This hierarchical structure minimizes the contact area between water and the surface, causing droplets to bead up and roll away, carrying dirt and contaminants with them.

Scientists and engineers have spent decades studying this natural phenomenon, seeking to replicate its properties for practical applications. The lotus effect has become the gold standard for superhydrophobic surfaces, inspiring innovations across industries from textiles to aerospace engineering.

⚗️ The Science Behind Superhydrophobicity

To understand how the lotus effect works, we need to explore the fundamental principles of surface tension and contact angles. When a water droplet sits on a surface, it forms a specific angle where the liquid meets the solid—this is called the contact angle. Surfaces with contact angles greater than 150 degrees are classified as superhydrophobic.

The lotus leaf achieves contact angles approaching 170 degrees through its unique microstructure. The combination of microscopic papillae (small bumps) ranging from 5 to 10 micrometers in height, covered with even smaller nanoscale waxy crystals, creates air pockets that prevent water from penetrating the surface structure.

The Two-Tier Architecture

The effectiveness of lotus-inspired hydrophobicity relies on this dual-scale roughness:

- Microscale features: Larger bumps that create the initial barrier to water penetration

- Nanoscale structures: Tiny waxy crystals that further reduce contact area and enhance water repellency

- Low surface energy: The waxy coating chemically resists adhesion to water molecules

- Air cushion effect: Trapped air between structures supports water droplets, minimizing solid-liquid contact

This combination creates what scientists call the “Cassie-Baxter state,” where water sits primarily on air pockets rather than the solid surface itself. The result is not just water repellency, but self-cleaning properties that make these surfaces remarkably resistant to contamination.

🔬 Engineering the Lotus Effect on Capture Surfaces

Translating nature’s design into engineered materials presents significant challenges. Capture surfaces—materials designed to intercept, collect, or interact with liquids—benefit tremendously from lotus-effect properties, but creating durable, scalable superhydrophobic coatings requires sophisticated manufacturing techniques.

Modern fabrication methods include laser etching, chemical vapor deposition, electrospinning, and sol-gel processes. Each technique offers distinct advantages depending on the substrate material, intended application, and performance requirements.

Laser Texturing Technology

Femtosecond laser technology has emerged as a powerful tool for creating lotus-inspired microstructures on metal, ceramic, and polymer surfaces. By precisely ablating material at the microscopic level, engineers can create patterns that mimic the lotus leaf’s hierarchical architecture with remarkable fidelity.

This method offers exceptional control over feature size, density, and distribution, allowing customization for specific applications. The process is also relatively environmentally friendly, requiring no chemical treatments or additional coatings in many cases.

Nanoparticle Coatings

Another approach involves applying nanoparticle suspensions that self-assemble into superhydrophobic structures. Silica nanoparticles, titanium dioxide, and carbon nanotubes have all been successfully used to create lotus-effect surfaces through spray coating, dip coating, or spin coating techniques.

These coatings can be applied to complex geometries and large surface areas, making them particularly attractive for industrial applications. The challenge lies in ensuring long-term durability and adhesion to the substrate material.

💧 Applications Transforming Industries

The potential applications of lotus-effect capture surfaces span virtually every industry where liquid-surface interactions matter. From preventing ice formation on aircraft wings to keeping solar panels clean in dusty environments, superhydrophobic technology is reshaping what’s possible.

Aerospace and Transportation

In aviation, ice accumulation on wings and control surfaces poses serious safety risks. Lotus-effect coatings prevent water from adhering long enough to freeze, offering a passive de-icing solution that could reduce reliance on energy-intensive heating systems. Similarly, automotive manufacturers are exploring superhydrophobic windshields that would require minimal wiper action and enhance visibility during rain.

Medical and Healthcare Settings

Hospital-acquired infections remain a critical challenge in healthcare. Superhydrophobic surfaces in medical facilities could dramatically reduce bacterial colonization, as microorganisms struggle to attach to surfaces where water cannot establish stable contact. Surgical instruments, catheters, and diagnostic equipment all stand to benefit from these self-cleaning properties.

Energy Sector Innovations

Solar panel efficiency drops significantly when dust, dirt, or water spots accumulate on the surface. Lotus-effect coatings allow panels to self-clean during rain events, maintaining optimal performance without manual intervention. In regions with limited water resources, this technology eliminates the need for water-intensive cleaning operations.

Textile and Apparel Industry

Water-repellent fabrics have been available for decades, but lotus-inspired nanotechnology takes performance to unprecedented levels. Modern superhydrophobic textiles resist not just water but also oil-based stains, while remaining breathable and comfortable. Military applications include uniforms that resist chemical contamination, while consumer products range from stain-proof upholstery to self-cleaning shoes.

🎯 Capture Surface Optimization Strategies

Designing effective lotus-effect capture surfaces requires balancing multiple performance parameters. The optimal configuration depends heavily on the specific application context and environmental conditions.

| Parameter | Impact on Performance | Optimization Approach |

|---|---|---|

| Microstructure density | Higher density increases contact angle but may trap contaminants | Application-specific tuning based on particle size and liquid properties |

| Feature height | Taller structures enhance repellency but reduce durability | Balance between performance and mechanical resilience |

| Chemical coating | Determines surface energy and chemical resistance | Select materials compatible with operating environment |

| Substrate material | Affects adhesion, thermal stability, and manufacturing method | Match treatment technique to substrate properties |

Engineers must also consider the dynamic behavior of droplets on these surfaces. The rolloff angle—the tilt required for water to begin moving—is as important as the static contact angle. Surfaces with low rolloff angles demonstrate superior self-cleaning because droplets can be displaced by minimal gravitational or wind forces.

⚡ Overcoming Durability Challenges

One of the most significant obstacles to widespread adoption of lotus-effect surfaces is their susceptibility to mechanical damage. The delicate micro and nanostructures that create superhydrophobicity can be easily worn away through abrasion, crushing, or repeated contact.

Recent research has focused on creating robust superhydrophobic surfaces that maintain performance under real-world conditions. Strategies include reinforcing nanostructures with protective coatings, developing self-healing materials that can regenerate damaged features, and designing armored surfaces where hydrophobic properties reside in protected recesses.

Self-Healing Superhydrophobic Materials

Inspired by biological systems, scientists have developed coatings that can repair minor damage autonomously. These materials incorporate reservoirs of low-surface-energy compounds that migrate to damaged areas, restoring water repellency. While still largely experimental, self-healing superhydrophobic surfaces represent a promising path toward long-lasting practical applications.

Mechanical Reinforcement Approaches

Another strategy involves creating hierarchical structures with mechanical resilience built into the design. By using stronger materials for the primary microscale features and protecting nanoscale structures within valleys or overhangs, engineers can create surfaces that withstand significant wear while maintaining superhydrophobic properties.

🌍 Environmental Considerations and Sustainability

As lotus-effect technology moves toward commercial scale, environmental impact becomes increasingly important. Traditional fluorinated compounds used in many water-repellent treatments have raised concerns about persistence in the environment and potential health effects.

The industry is shifting toward fluorine-free alternatives based on silicones, hydrocarbons, and biomimetic waxes. These materials can achieve comparable performance while offering better environmental profiles. Additionally, manufacturing processes are being refined to reduce waste, energy consumption, and hazardous chemical usage.

The self-cleaning properties of lotus-effect surfaces also contribute to sustainability by reducing the need for chemical cleaning agents and water consumption in maintenance operations. In large-scale applications like building facades or solar installations, these savings can be substantial over the lifespan of the installation.

🔮 Future Directions and Emerging Technologies

The field of biomimetic superhydrophobicity continues to evolve rapidly, with researchers exploring increasingly sophisticated approaches to water repellency. Smart surfaces that can switch between hydrophobic and hydrophilic states in response to environmental triggers represent one exciting frontier.

Responsive Superhydrophobic Systems

Imagine surfaces that could dynamically adjust their water-repellent properties based on conditions. Temperature-responsive materials could shed water when warm but allow wetting when cold, useful for applications requiring alternating collection and repulsion modes. Electrically switchable surfaces could enable precise control over droplet behavior in microfluidic devices and lab-on-a-chip systems.

Multifunctional Surface Integration

Future developments will likely combine lotus-effect properties with other functionalities. Surfaces that simultaneously repel water, kill bacteria, harvest energy, or change color are already under development. These multifunctional materials will enable entirely new application categories and performance levels.

Advanced Manufacturing Scalability

As production techniques mature, costs will decline and accessibility will improve. Roll-to-roll processing, additive manufacturing, and self-assembly methods promise to make superhydrophobic treatments economically viable for mass-market applications. The technology that once seemed like laboratory curiosity is rapidly approaching commodity status.

🚀 Implementing Lotus-Effect Solutions

Organizations considering lotus-effect capture surfaces for their applications should approach implementation strategically. Begin with a thorough analysis of performance requirements, environmental conditions, and success metrics. Pilot testing in representative conditions is essential before large-scale deployment.

Collaboration with materials scientists and surface engineers can help identify the optimal approach for specific needs. The choice between mechanical texturing, chemical coatings, or hybrid methods depends on factors including substrate material, expected service life, maintenance capabilities, and budget constraints.

Quality control and long-term monitoring are critical for ensuring sustained performance. Regular assessment of contact angles, rolloff behavior, and visual appearance can detect degradation before it impacts functionality, allowing timely maintenance or reapplication.

🌟 Unleashing Water Repellency’s Full Potential

The lotus effect represents more than just an interesting natural phenomenon—it embodies a fundamental rethinking of how we design material surfaces. By learning from millions of years of evolutionary optimization, we’ve unlocked capabilities that seemed impossible just decades ago.

Capture surfaces enhanced with lotus-inspired hydrophobicity are transforming industries, solving longstanding problems, and enabling innovations that would otherwise be impractical. From keeping aircraft safe to maintaining solar panel efficiency, from reducing hospital infections to creating stain-proof clothing, superhydrophobic technology touches virtually every aspect of modern life.

As manufacturing techniques advance and costs decrease, lotus-effect surfaces will become increasingly ubiquitous. The next generation of buildings, vehicles, medical devices, and consumer products will incorporate these capabilities as standard features rather than premium additions.

The journey from observing a pristine lotus leaf in a muddy pond to engineering advanced superhydrophobic capture surfaces demonstrates humanity’s capacity to learn from nature and apply those lessons to solve pressing challenges. As we continue refining these technologies, we move closer to realizing the full potential of ultimate water repellency—creating a cleaner, more efficient, and more sustainable world through the power of biomimetic surface engineering.

The future of surface science is being written in water droplets that refuse to stay put, rolling away and carrying with them the promise of materials that stay cleaner, perform better, and last longer than ever before. The lotus effect has moved from botanical curiosity to technological imperative, unleashing possibilities that continue to expand as our understanding deepens and our capabilities grow.

Toni Santos is a water systems researcher and atmospheric resource specialist focusing on the study of air-to-water condensation cycles, atmospheric water harvesting technologies, bio-inspired capture surfaces, and desalination integration models. Through an interdisciplinary and engineering-focused lens, Toni investigates how humanity can extract freshwater from air and optimize water generation systems — across climates, technologies, and emerging solutions. His work is grounded in a fascination with water not only as a resource, but as a carrier of innovation and sustainability. From atmospheric water generation to biomimetic surfaces and hybrid desalination systems, Toni uncovers the technical and systemic tools through which engineers advance humanity's relationship with water scarcity and climate adaptation. With a background in environmental engineering and water resource technology, Toni blends system analysis with practical research to reveal how condensation cycles are used to generate water, optimize efficiency, and integrate renewable hydration sources. As the creative mind behind delvryos, Toni curates technical taxonomies, scalable water studies, and system interpretations that advance the critical connection between atmospheric capture, surface design, and sustainable desalination. His work is a tribute to: The renewable potential of Air-to-Water Condensation Cycles The innovative methods of Atmospheric Water Harvesting Technologies The nature-inspired design of Bio-Inspired Capture Surfaces The synergistic frameworks of Desalination Integration Models Whether you're a water engineer, sustainability researcher, or curious explorer of atmospheric hydration systems, Toni invites you to explore the evolving science of water generation — one droplet, one surface, one innovation at a time.